Technologies &Products

Acoustics

Acoustics: A New Era of Sound Control

Conventional acoustic insulation relies on bulk and mass, but MetaDyna’s metamaterials redefine sound control by manipulating the physics of sound itself. Our technology utilizes engineered internal cavities and thin structures to create precise viscous and thermal interactions that convert sound into heat. Simultaneously, integrated resonant spaces generate inverse waves to cancel incoming noise through controlled interference. This dual-action approach allows our ultra-thin and tunable metamaterials to deliver superior acoustic performance without the weight or volume of conventional materials.

Meta Panel: High-Impact Control at Just 1 cm

The Meta Panel redefines the limits of thin-profile acoustic solutions, offering laboratory-grade performance in a fraction of the space.

- Performance: 28 dB sound absorption.

- Range: Broad frequency coverage from 50 Hz to 10,000 Hz.

- Ultra-Thin: Only 1 cm thickness.

- Geometry-Driven: Performance is determined by engineered form, not material mass.

- Ideal for: Space-restricted and weight-sensitive applications where every millimeter counts.

MetaBack: High-Performance Acoustic Enhancement

MetaBack elevates standard passive materials by integrating our proprietary metamaterial architecture (mQWM) into existing product layers.

- Efficiency: Achieves up to 90% sound absorption.

- Isolation: Provides 25 dB superior insulation at critical low and mid frequencies.

- Low Profile: Adds only 1 cm of additional thickness.

- Integration: Designed to work seamlessly with existing passive materials and industrial manufacturing processes.

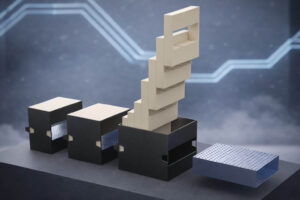

Meta Bricket: Frequency-Targeted Engineering

The Meta Bricket offers total geometric freedom, allowing engineers to “tune” the product to specific environmental noise profiles.

- Precision Tuning: Target frequencies are adjusted via unit height, while performance intensity is shaped by unit width.

- Compact Superiority: Meta Bricket delivers industry-leading performance at just one-sixth the thickness of conventional acoustic materials.

- Versatile Models: Available in 8 standard (M1–M8) and 4 special (S1–S4) models that can be combined for customized broadband coverage starting from 100 Hz.

- Acoustic Benefits: Impedance-matched architecture reduces sound reflection and allows deep penetration of randomly incident waves, significantly boosting low-frequency absorption.

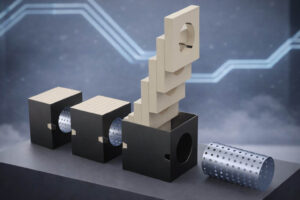

HVAC Meta-Silencer: Flow Acoustic Precision

The HVAC Meta-Silencer redefines ventilation acoustics by enabling superior noise suppression without obstructing airflow. Unlike traditional bulky silencers that create high pressure drops, our modular meta-cells allow air to pass freely while trapping noise through engineered geometric resonance.

- Modular Frequency Control: Features a 3-stage modular architecture designed to be stacked in sequence to neutralize specific noise profiles:

Low-Frequency Module: Targets the 100–200 Hz range.

Mid-Frequency Module: Optimized for 200–500 Hz.

High-Frequency Module: Covers 500–10,000 Hz for broadband clarity.

- Zero-Obstruction Design: Engineered with open-cell meta-architectures that ensure maximum airflow with minimal pressure loss, significantly increasing system energy efficiency.

- Compact Integration: Delivers industrial-grade silencing at a fraction of the length of conventional dissipative silencers, fitting easily into tight duct spaces.

- Customizable Stacking: Modules can be combined or repeated based on the specific environmental noise requirements, allowing for a “tunable” silencing solution.

- Ideal for: Data centers, high-end commercial HVAC systems, and industrial ventilation where quiet operation and airflow efficiency are equally critical.

| Feature | Meta Panel | MetaBack | Meta Bricket | Meta HVAC Silencer | Conventional |

|---|---|---|---|---|---|

| Primary Function | Standalone high-impact insulation | Enhancement of existing passive materials | Frequency-targeted precision tuning | Airflow noise suppression via modular meta-cells | Bulk absorption and barrier protection |

| Standard Thickness | 1 cm | 1-4 cm | Varied (1/6th of conventional depth) min(2.4cm) | Thin modular units (stackable) | 5 – 15 cm (to match meta-performance) |

| Acoustic Performance | 28 dB Sound Absorption | Up to 90% Absorption / 25 dB Insulation | Custom-tuned via unit geometry up to 95% Absorption | Up to 80% Absorption | High at high frequencies; Poor at low frequencies |

| Frequency Range | Broadband (50 – 10,000 Hz) | Low to Mid Frequency focus | High-precision targeted frequencies |

Modular Coverage: Low: 100–200 Hz Mid: 200–500 Hz High: 500–10k Hz |

Limited (Mostly High Frequencies >500 Hz) |

| Best For | Space-restricted & weight-sensitive areas | Elevating standard insulation layers | White goods, Automotive, Aerospace | Designed for open-air passage with zero blockage | General insulation where space is not an issue |

| Design Flexibility | Flat or slightly curved surfaces | Seamless industrial integration | Total geometric freedom (Bar or Plate) | Stackable & Modular: Can be combined based on target noise | Limited to standard shapes and heavy layers |

| Key Advantage | Maximum thinness for wide-range control | Dramatically boosts passive performance | Achieves low-frequency targets at 16% volume | High performance in low frequencies without blocking air | Low initial cost but high volume/weight penalty |

Choosing the Right Technology

Select Meta Panel when you have severe space constraints but require a high-fidelity, standalone solution across a wide frequency spectrum.

Select MetaBack if you are already using traditional materials and want to significantly boost their efficiency (especially in low-mid ranges) without adding significant bulk.

Select Meta Bricket for specialized engineering projects where you need to “cancel out” specific resonant frequencies using a modular, highly adaptable form factor.

Let’s Redefine Performance Limits

Creating application-specific meta-solutions through advanced engineering and collaboration.

Have Any Question?

Metadyna, we design next-generation meta-structures that reshape how waves and forces behave-sound, vibration, shock and kinetic energy.

Quick Link

Contact Us

Phone

+90 232 453 00 52

info@metadyna.com